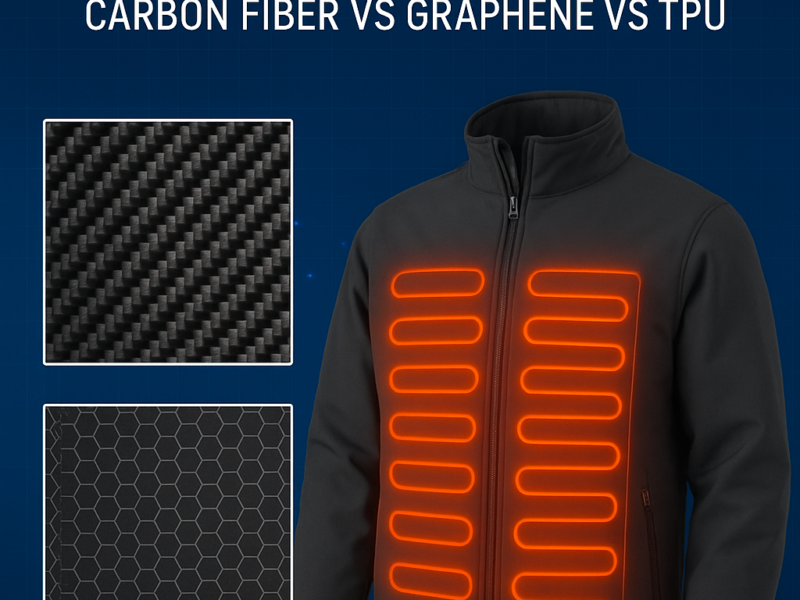

Heated apparel has evolved far beyond bulky battery packs and stiff wires. Today’s innovation lies in ultra-thin heating technology seamlessly integrated into vests, jackets, gloves, and even base layers.

If you are developing a heated apparel line, choosing the right heating element will directly impact your product’s weight, flexibility, efficiency, lifespan, and user experience.

In this guide, we compare the three most common heating technologies—Carbon Fiber, Graphene Film, and TPU Laminated Heating Sheets—so you can select the right option for your target market and brand positioning.

🔬 1. Carbon Fiber Heating Elements

Carbon fiber remains the most widely used heating material in heated clothing, thanks to its balance of cost, performance, and durability.

✅ How It Works

Carbon fibers conduct electricity and generate heat through resistance. They are usually stitched or laminated inside the garment across multiple zones (e.g., back, chest, neck).

Pros

- Fast heating (5–10 seconds)

- Flexible and lightweight

- Cost-effective for mass production

- Long lifespan (>500 uses)

- Works at low voltage (5V / 12V)

Cons

- Slightly thicker than graphene films

- Less efficient for full-surface heat coverage

📦 Best For

Entry-to-mid level heated vests, cost-sensitive projects, and workwear.

💡 YubinGlobal Insight: Our ODM heated vest line uses optimized carbon fiber grids for uniform warmth and minimal bulk.

🧪 2. Graphene Film Heating

Graphene is one of the most advanced heating materials—only one atom thick yet exceptionally conductive and efficient.

✅ How It Works

Graphene films are printed or layered between protective fabrics, creating an ultra-thin, responsive heating panelwith even heat dispersion.

Pros

- Ultra-thin (<0.3 mm)

- Even heating across the entire surface

- Energy-efficient (up to 20% power savings)

- Lightweight and breathable

- Silent operation

Cons

- Higher material & production costs

- Limited supply of premium-grade graphene

- Requires precise voltage regulation

📦 Best For

Premium heated jackets, base layers, and lightweight outdoor performance wear.

💡 YubinGlobal Insight: We offer OEM graphene production with third-party testing and durability validation (80+ wash cycles).

🧰 3. TPU Laminated Heating Sheets

TPU (Thermoplastic Polyurethane) laminated heating is an emerging technology ideal for waterproof and durable applications.

✅ How It Works

Conductive circuits are printed onto TPU film, then laminated inside garments to create waterproof, windproof heating panels.

Pros

- Fully waterproof and windproof

- Durable for frequent wash & fold

- Smooth surface (no wire feel)

- Great for large flat heating zones

Cons

- Less breathable than fabric-based heaters

- Slightly stiffer than carbon fiber or graphene

- Less adaptable for multi-zone designs

📦 Best For

Rainwear, snowmobile gear, heated seats, or back-support apparel.

💡 YubinGlobal Insight: We produce in-house TPU heating modules for OEM clients in Canada and Northern Europe.

📊 At-a-Glance Comparison Table

| Feature | Carbon Fiber | Graphene Film | TPU Sheet |

|---|---|---|---|

| Thickness | ~1–2 mm | ~0.3 mm | ~0.5–1 mm |

| Flexibility | High | Ultra-high | Medium |

| Heat Distribution | Good | Excellent | Moderate |

| Energy Efficiency | Standard | High | Moderate |

| Cost | Low | High | Medium |

| Best Use Case | Workwear, vests | Premium jackets | Rain/snow gear |

🧩 Choosing the Right Heating Technology

| Brand Positioning | Recommended Heating Type |

|---|---|

| Entry-level winter vest | Carbon Fiber |

| Ultra-lightweight techwear | Graphene |

| Rugged outdoor waterproof | TPU Sheet |

| Fashion-meets-function | Carbon Fiber or Graphene |

| First-time Amazon seller | Carbon Fiber ODM |

Key Takeaway: Not every market needs the highest-tech option. Your heating element should match your customers’ budget, climate, and usage scenario.

🛠 How YubinGlobal Supports OEM Clients

We provide:

- R&D consultation on heating element selection

- Custom heating pattern layouts for different garments

- Performance & wash durability testing

- Certification support (CE, UL, UN38.3, etc.)

We don’t believe in “one-size-fits-all”—we engineer heating systems tailored to your brand.

✅ Final Thoughts

Choosing between carbon fiber, graphene, and TPU heating is not just a technical decision—it’s a brand-defining choice.

If you want to turn your concept into a market-ready heated gear line with the right balance of performance, compliance, and cost efficiency, our engineering team is here to help.

📩 Email: info@yubinglobal.com

Recent Comments